Our History

In 1982 Midwest Die Corp was formed by brothers Rodney and Gary Nitz along with friend and neighbor Ray Kinnison. Setting up shop in the back of Ray’s welding business, Rod and Gary pursued their dream of owning a tool shop. Gary was a seasoned journeyman mold maker then, and Rod was still drying the ink on his certificate.

In 1984 Rod and his cousin Richard Nitz partnered, as Gary and Ray chose to move on to other employment and business opportunities. Richard was also a seasoned mold maker and had always wanted to own a shop. They decided to move the equipment to a rental facility in downtown Baroda where they remained for the next 16 years.

In 1984 Rod and his cousin Richard Nitz partnered, as Gary and Ray chose to move on to other employment and business opportunities. Richard was also a seasoned mold maker and had always wanted to own a shop. They decided to move the equipment to a rental facility in downtown Baroda where they remained for the next 16 years.

In 1991 the Nitz’s decided it was a time that Midwest Die has a place to call home and built a new 8,000 sq. ft., climate-controlled facility in the industrial district of Baroda. A 2,000 sq. ft. storage facility followed in 1996. After the “great recession,” it was time to add another 8,000 sq. ft. of manufacturing space to accommodate new equipment and facilitate growth. Currently, Midwest Die has approximately 20,000 sq. ft. under roof.

With dedicated and well-trained employees, investment in modern technologies, and attention to quality and customer service, Midwest Die has proven themselves as a trusted and sought after source for die cast tooling.

Our Capabilities

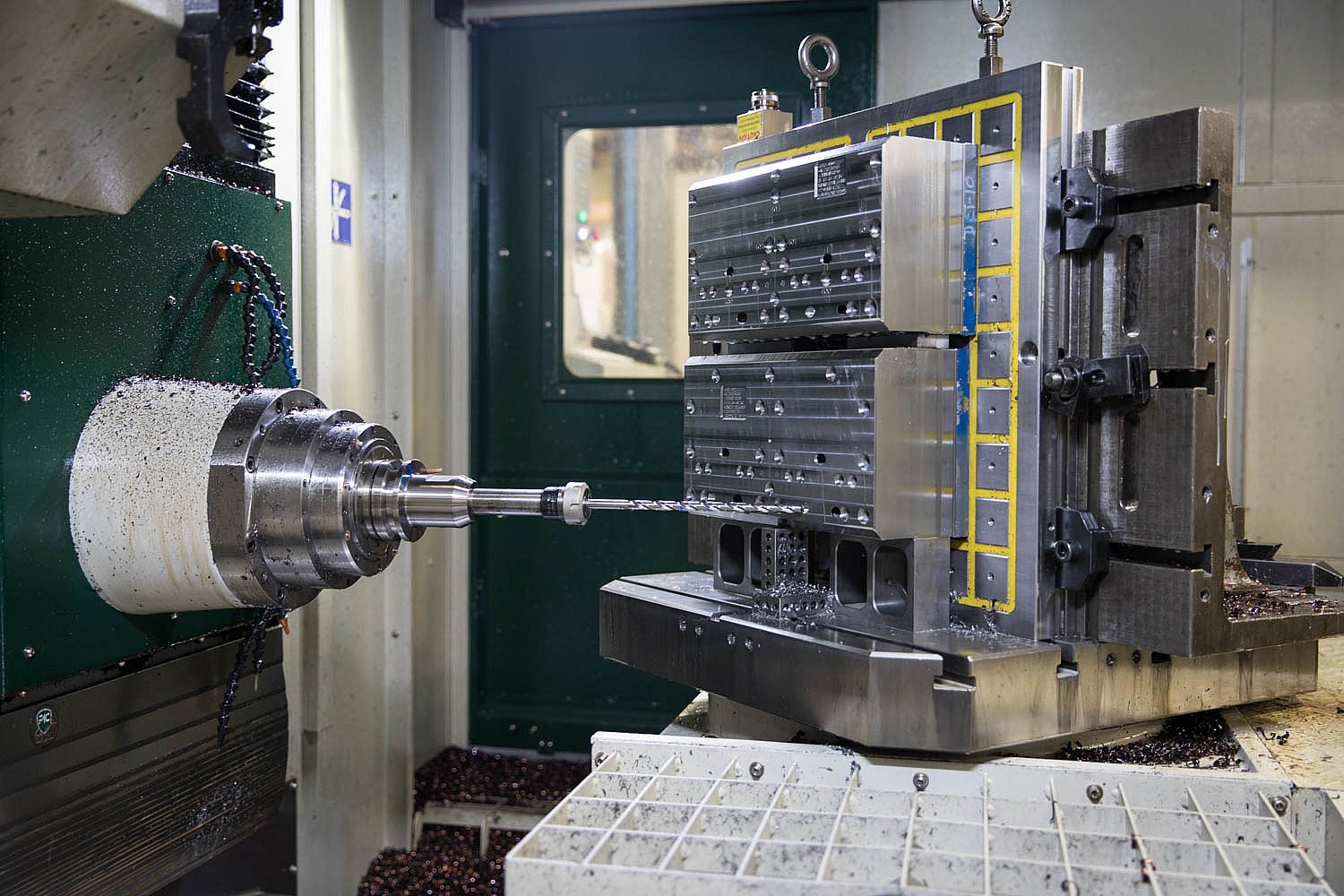

At Midwest Die Corp., we focus on producing the highest-quality die cast dies for aluminum, zinc, and magnesium. But we also manufacture dies that utilize beryllium copper. This amazing copper alloy has the tensile strength of steel but the heat-transfer properties of copper.

Our 13 CNC machines and two EDM machines enable us to work to tolerances of +/- 0.001” for most projects. Extremely delicate work, such as splines, will require tolerances of +/- 0.0005”.

Equipment List and Specifications

| Machine Make / Model | Type | Axis Travels | Spindle | Max. | Workpiece Limitations | Notes / Features / Vintage | ||||

| X | Y | Z | to Table | RPM | Wt. (lbs.) | Size - X | Size - Y | |||

| Haas VF-2YT | Vert. Mach. Ctr. | 30.00 | 20.00 | 20.00 | 24.00 | 8K | 3000 | Thru Spindle Coolant 2014 | ||

| Haas VF-2YT | Vert. Mach. Ctr. | 30.00 | 20.00 | 20.00 | 24.00 | 8K | 3000 | Thru Spindle Coolant 2018 | ||

| Haas VF-6 | Vert. Mach. Ctr. | 63.00 | 31.00 | 30.00 | 34.00 | 8K | 4000 | CE Control Retrofit in 2004 1998 | ||

| Creative Evol. HS-1100 | Vert. Mach. Ctr. | 43.00 | 23.50 | 21.50 | 29.50 | 24K | 2000 | 40 x 17 Pallet Changer 2004 | ||

| Creative Evol. FMC-850 | Vert. Mach. Ctr. | 33.50 | 20.00 | 21.00 | 27.50 | 12K | 1600 | 2006 | ||

| Creative Evol. FMC-1060 | Vert. Mach. Ctr. | 39.37 | 23.62 | 21.65 | 27.50 | 15K | 2000 | 43.3 | Koma Precision Rotary Table 2011 | |

| Creative Evol. FMC-1060 | Vert. Mach. Ctr. | 39.37 | 23.62 | 21.65 | 27.50 | 15K | 2000 | 43.3 | 40 x 17 Pallet Changer / TSC 2016 | |

| Creative Evol. HSD-500 | Carbon Cutter | 20.00 | 16.00 | 14.00 | 20.00 | 30K | 770 | 600 IPM Max Feedrate 2013 | ||

| Creative Evol. HMR-1189 | Hor. Mach. Ctr. | 43.00 | 31.00 | 35.00 | 10K | 1430 | 28" Rotary Table / TSC 2016 | |||

| Milltronics VM17 | Vert. Mach. Ctr. | 28.00 | 14.00 | |||||||

| Milltronics MB19 | Vert. Mach. Ctr. | 31.00 | 18.00 | 4K | ||||||

| Charmille Cut E 600 | CNC Wire EDM | 23.62 | 15.75 | 13.78 | 1000 | 40 | 31 | 2019 | ||

| Charmille Roboform 40 | CNC Sinker EDM | 19.50 | 15.75 | 23.50 | 120a | 2200 | 46 | 30 | EROWA, 6 Sta. Changer Retro 2002 | |

| (2) Bridgeport Series I | Vertical Mills | 9.00 | 42.00 | |||||||

| Bridgeport Series II | Vertical Mill | 12.00 | 56.00 | |||||||

| Kent | Surface Grinder | 60.00 | 24.00 | 1998 | ||||||

| Proth | Surface Grinder | 30.00 | 15.00 | 1985 | ||||||

| Haas ST-30 | CNC Lathe | 12.50 | n/a | 26.00 | 3400 | 21" dia | 12" 3-Jaw, 12-Pos. Turret 2014 | |||

| Victor 1640 | Toolroom Lathe | 16" dia | 1985 | |||||||

| DeVleig KM3B | Hor. Boring Mill | 6000 | 48 | 30 | Ancient | |||||

| Wells | Hor. Cut-off Saw | 18.00 | inf. | 16.00 | ||||||

| Wells | Scissor Saw | 9.00 | inf. | 15.00 | ||||||

| Material Handling | Bridge Cranes: (2) 5-ton, (1) 7.5-ton, (1) 10-ton, (7) Jib Cranes, 5 & 12k Forklifts, (3) 1/2 ton p/u's & (1) 32k GVRW truck | |||||||||

| CAD / CAM | CAD: (3) Siemans NX 11.0, (2) AutoCad Mechanical CAM: (1) Siemans NX 11.0, (3) Surfcam | |||||||||

The Automotive Experts

We’re experts in producing die cast dies for the automotive industry. For more than 35 years, we’ve been instrumental in the manufacture of the following die cast parts:

- Structural parts (such as brackets) for automotive suspension and power steering pumps

- Transmission housings

- Power steering housings

- Bell housings

- Compressor housings

- Engine manifolds

- Gas meter housings

- Water meter housings

- Regulators

- Valves

- Rack and pinion steering tools (for both electric and hydraulic steering)

- Motorcycle brake handles and clutch handles

And More…

But that’s not all. At Midwest Die we also make superior die cast dies for:

But that’s not all. At Midwest Die we also make superior die cast dies for:

- Power tool housings

- Hardware brackets

- Heat sinks for electronics and electrical components

- Appliances

- Consumer products

In fact, we serve a multitude of industries, in addition to automotive and electronics, including:

- Recreation (boating, hunting, fishing, off-road, archery)

- Medical

- Energy Generation

- Aerospace

- Heavy Equipment

- Defense

- Furniture

Our end-users include:

- John Deere and other heavy equipment manufacturers

- General Motors

- Chrysler Automotive

- Ford

- Honda

- Nisson

- Mercedes

- Detroit Diesel

- Harley Davidson

- Haworth Furniture

- Steel Case Furniture

And to keep us abreast of the industry’s most current technological trends and manufacturing processes, we maintain membership in the following associations:

- American Mold Builders of Association (AMBA)

- North American Die Casting Association (NADCA)

- Berrien Tooling Coalition

Trust Us

You can trust the professionals at Midwest Die Corp. to produce for you an exceptional die cast die for optimal accuracy and productivity. Our keen attention to detail has made us the industry experts since 1982.

You’ll see…The Difference Is in the Details!